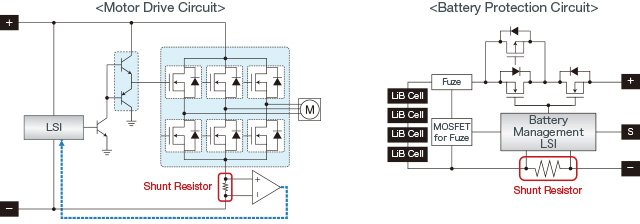

Thanks to its high level of modularity almost any motor value can be measured and integrated with monitoring values of gearbox and end application e g.

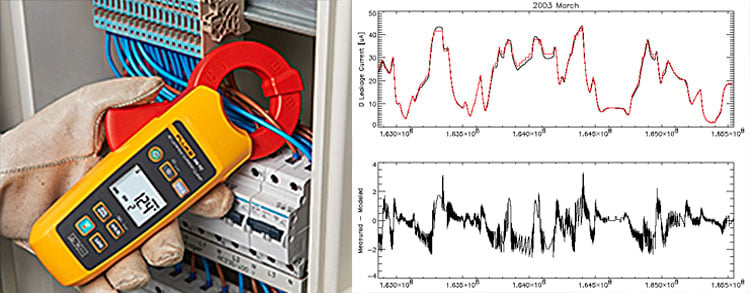

Motor current monitoring system.

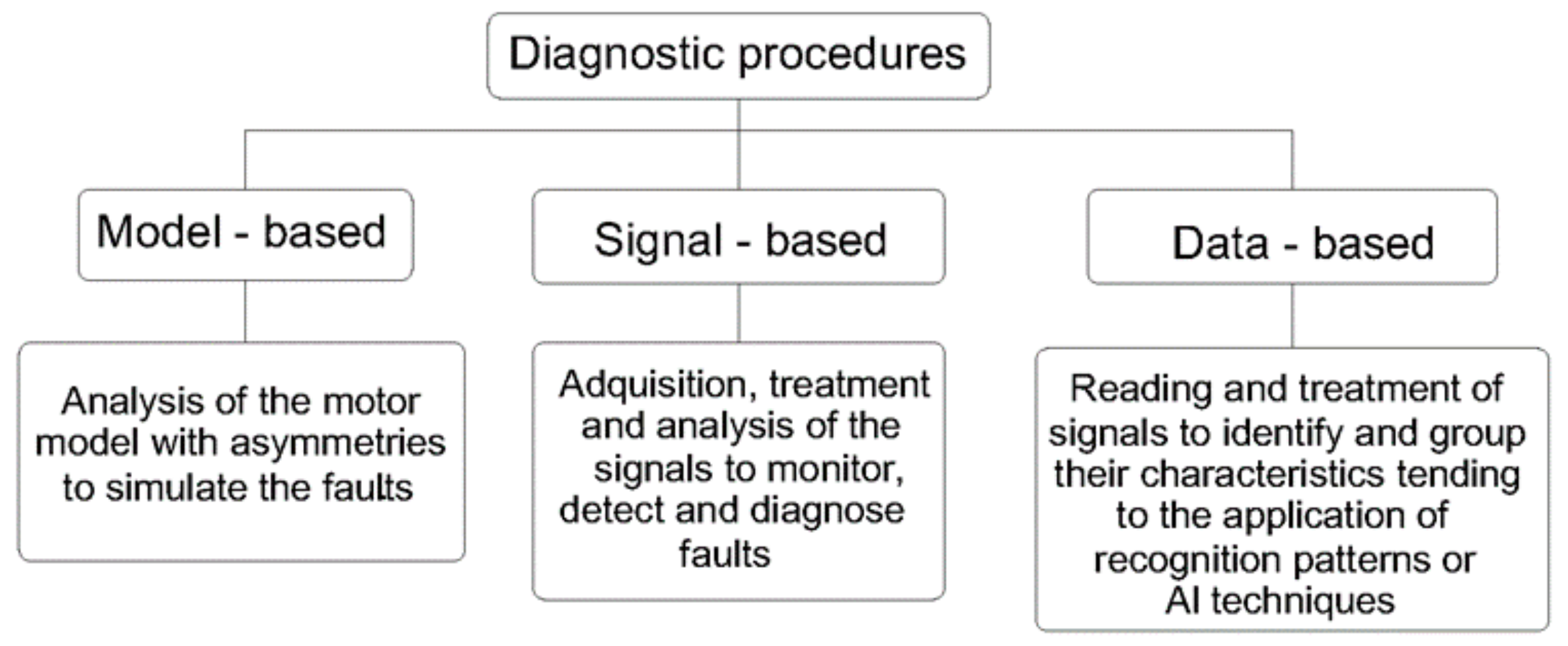

Iris power provides the sensors instruments diagnostic software and services needed to ensure your condition monitoring program provides the information required for you to understand the health of your motor fleet prioritize corrective measures and plan maintenance outages prior to failures.

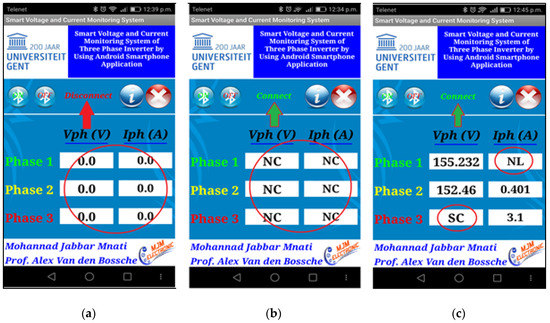

Such a technology allows for real time online monitoring of various motor parameters such as voltage current temperature and speed.

Current monitoring with undercurrent monitoring you can monitor electrical loads for functionality or open circuit.

The system measures most important motor values and allows plant personnel to get full insight into the motor health.

Overcurrent monitoring enables you to prevent overload situations or blockages.

Independent monitoring of essential elements monitor current flow to lights heating coils motors and other vital components within a system.

Contact a distributor find a sales office.

Pump fan turbine e c.

Ecsc series compact currentwatch current switches ac dc current switches for detecting ac current above 0 5 a trip point.

Motor control and monitoring systems also called intelligent control devices enable remote starting controlling stopping and monitoring of motors through a motor control module.